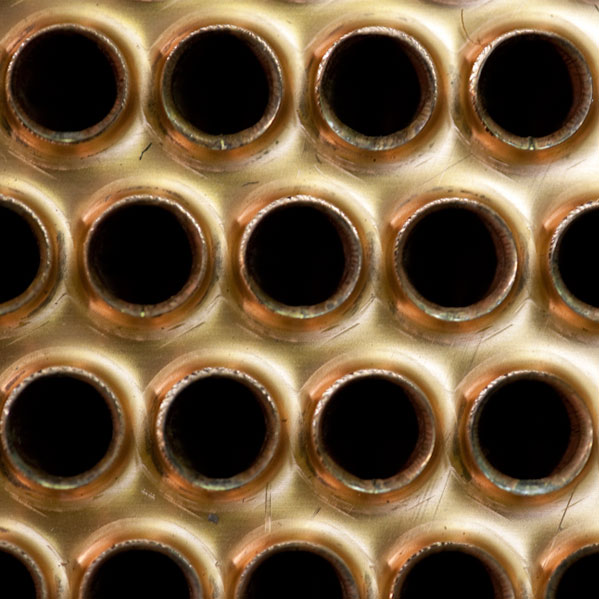

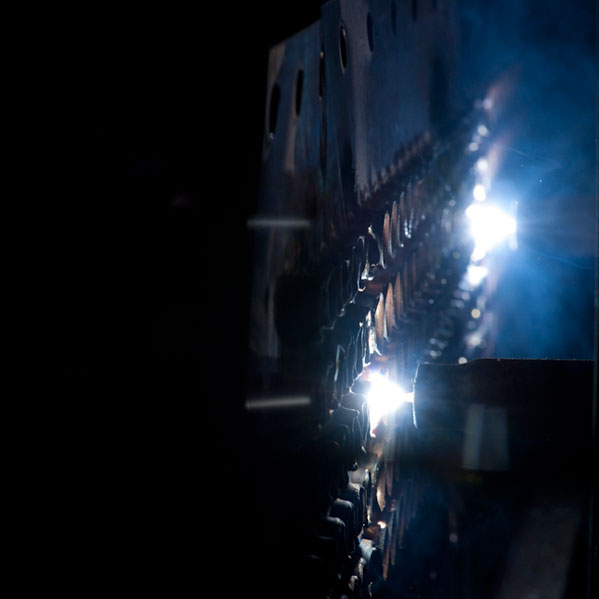

The fusion welded joint at the junction of the tube ends and header plate creates the primary mechanical joint, while solder back-fill facilitates sealing of the joint. The added mechanical support provided by the solder fillet also aids in distribution of mechanical stresses.

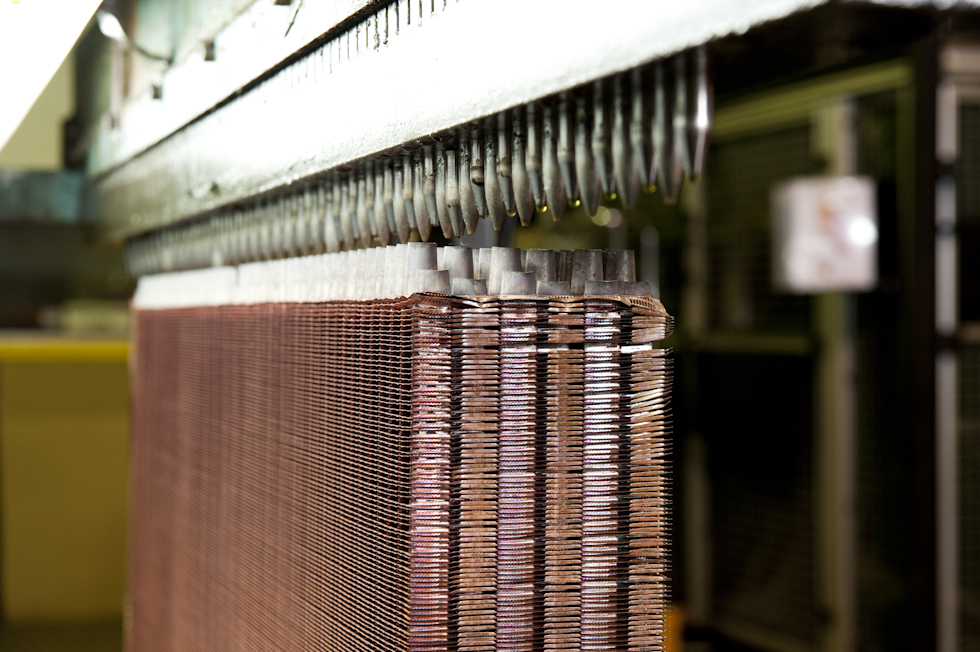

Ultra Fused is a field proven technology with over 15 years application experience in a variety of installations including heavy truck, bus, mining and earth moving equipment, rail (locomotives, DMU’s), defense equipment and power generation.

Independent tests have shown that Ultra-Fused is up to 20 times stronger than conventional soft soldered tube-to-header joint designs.

Ultra Fused is a key component in Air Radiators suite of products that allow the company to provide tailored, fit-for-purpose engine cooling system solutions.